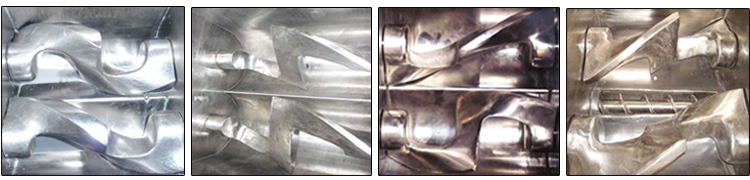

Faucets with Z-shaped blades

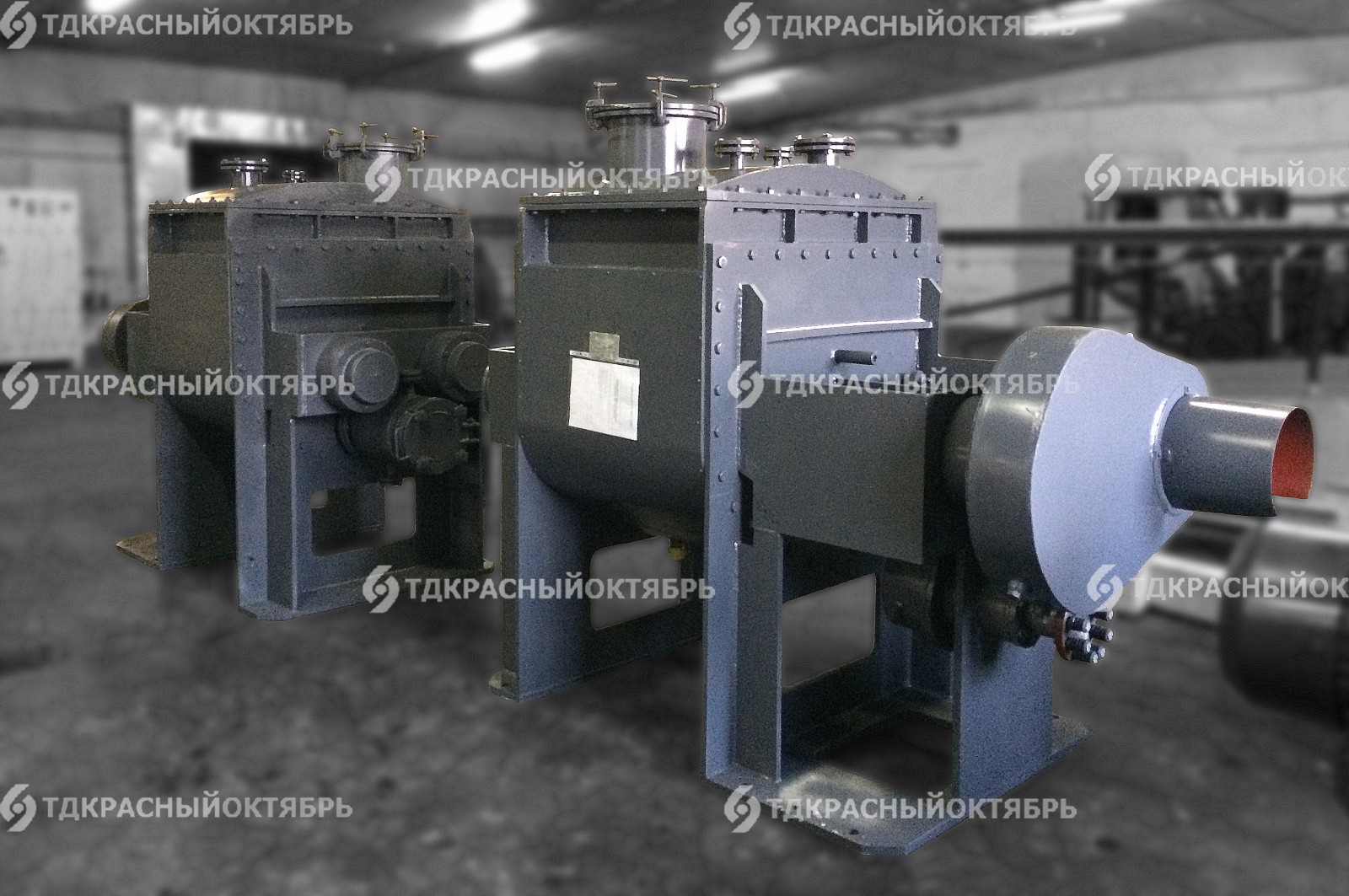

Mixers type ZL and ZSH

Double-roll mixers of batch type ZL and ZSH are designed for kneading and stirring with simultaneous heating or cooling of various semi-solid masses, pastes, putties, glue, soft mushy masses, soft plastics and other substances of similar consistency.

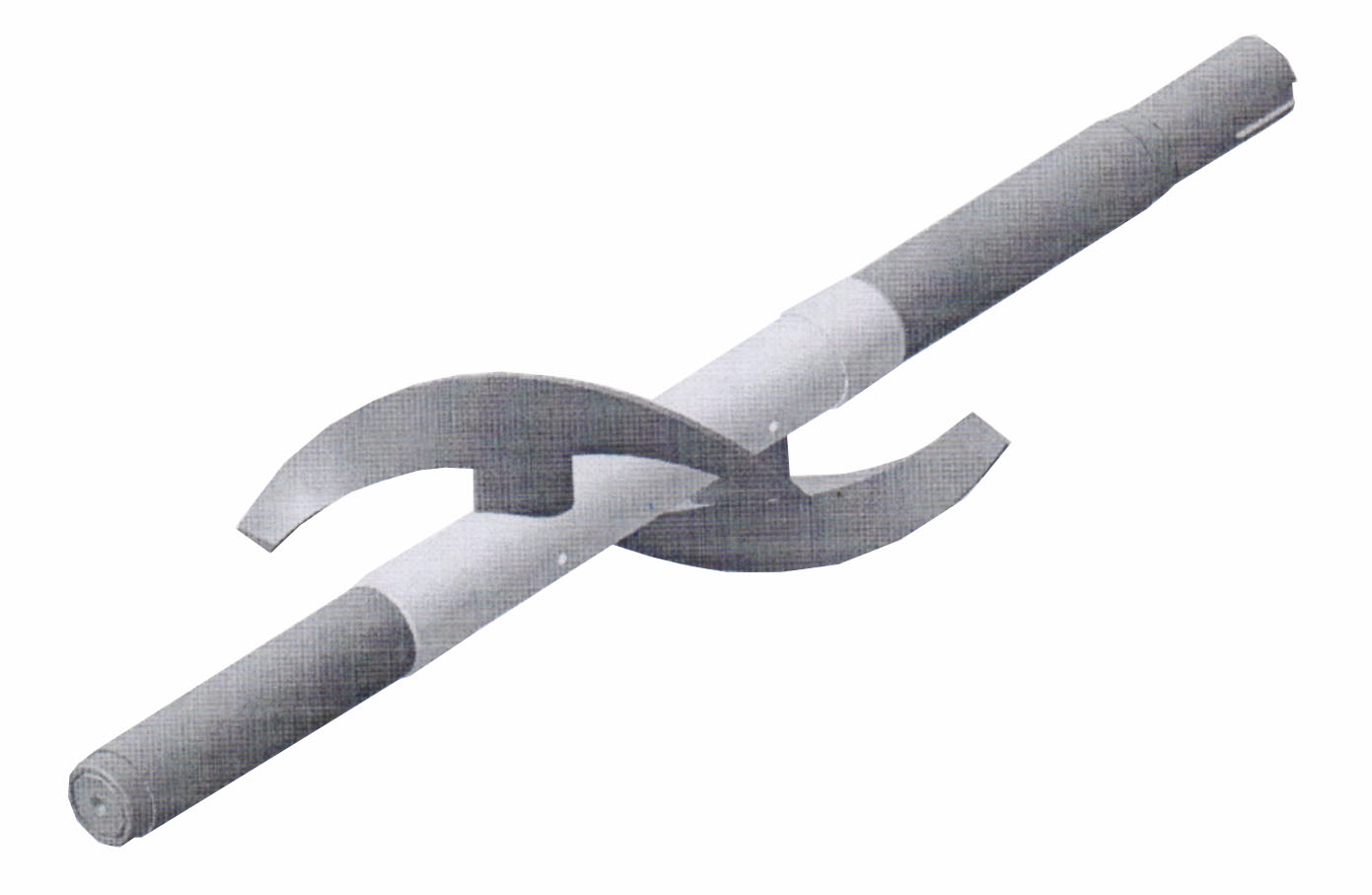

Mixers are a mixing machine, the working bodies of which are two horizontally arranged Z-shaped vane rollers rotating in opposite directions, with different speeds, with roll rotation being reversible.

The rolls rotate in a special shaped trough, which is closed from the sides by the end walls, and above - by a dustproof lid.

The rollers are driven by the electric motor through an elastic coupling, a reduction gear and an equalizing clutch.

The main product is loaded into the housing through the hatch in the lid or with the lid open, and additional components through the process connections. In ZL mixers, the finished product is unloaded when the lid is opened after the body is tilted 110 ° from the horizontal plane by means of a hydraulic cylinder.

In mixers type ZSH the finished product is unloaded with the lid closed by squeezing the product with a screw. The auger has a heated casing, a flange connection. A pipeline, spinneret, etc. can be connected to the flange connection. of corrosion-resistant steel or of carbon steel with lining with corrosion-resistant steel of grade 12Х18Н10Т.

The main drive and the drive of the overturning mechanism or auger discharge are equipped with electric motors of a single series AIR (4A) with a voltage of 380V or explosion-proof electric motors of the AIM (VAO) series with a voltage of 380V with an explosion protection level of at least 1ЕхdІІВТ4.

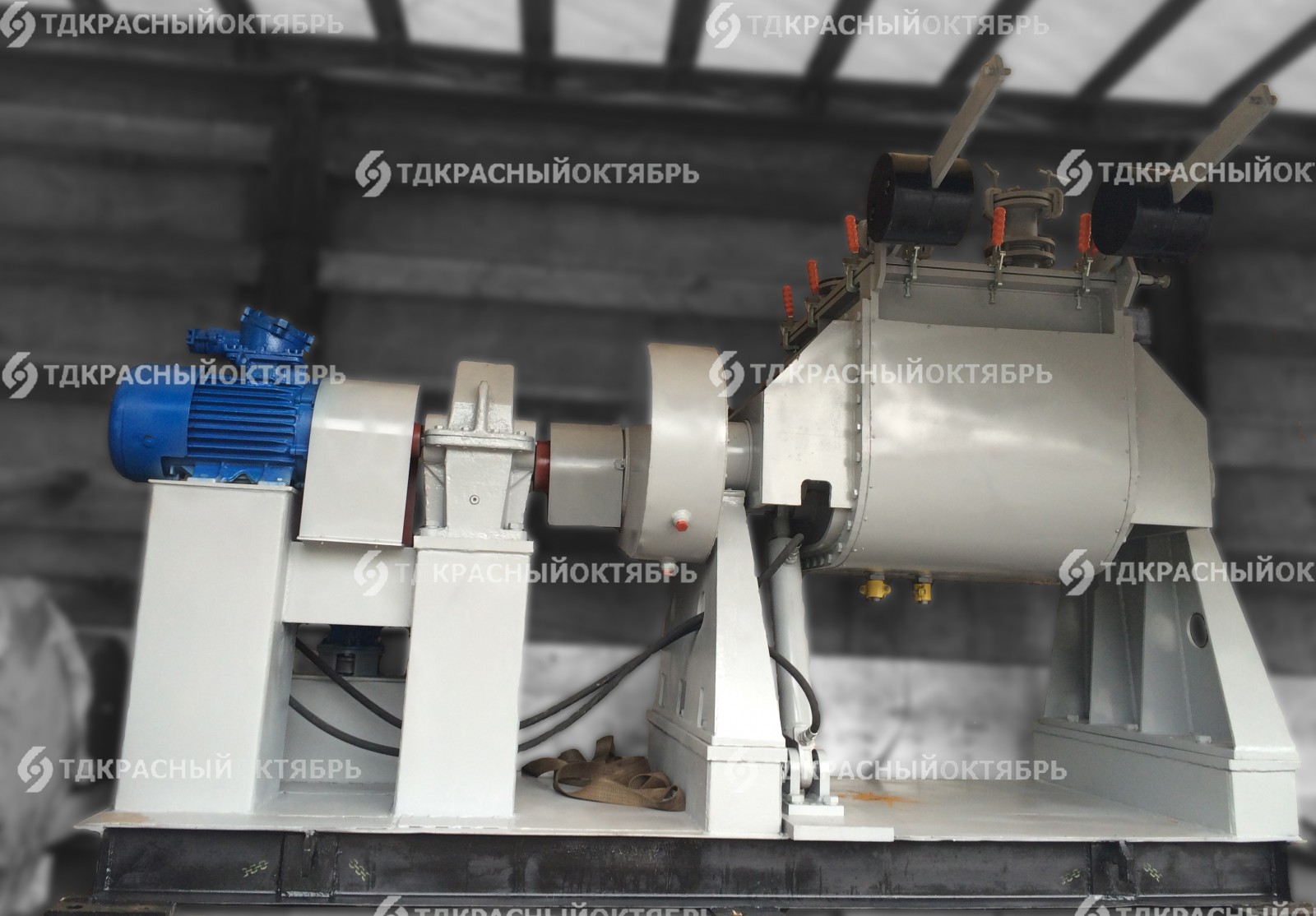

Mixers of periodic action of type ZL

In ZL mixers, the finished product is unloaded with the lid open after the hull has been tilted 110 ° C from the horizontal plane by means of a hydraulic cylinder.

Characteristics of batch mixers type ZL

| Mixer size | Working volume, m3 | Rotational speed of slow-speed rotor, s-1 | High speed rotor speed, s-1 | Working temperature, °С | Installed power, kW | Pressure in the chamber, MPa | Pressure in the shirt, MPa | Overall dimensions max, mm | Weight max, kg | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| length | width | height | |||||||||

| ZL-1 | 0,001 | 0,57 | 0,75 | to +150 | 0,55 | 0,01 | 0,6 | 1030 | 320 | 330 | 82,5 |

| ZL-10 | 0,01 | 0,69 | 1,18 | to +160 | 2,2 | 1529 | 630 | 712 | 398 | ||

| ZL-63 | 0,063 | 0,69 | 1,18 | -20 to +160 | 4 | 1805 | 1125 | 1450 | 1490 | ||

| ZL-100 | 0,1 | 0,67 | 1,0 | 7,5 | 0,02 | 2000 | 920 | 1620 | 2265 | ||

| ZL-250 | 0,25 | 0,44 | 0,77 | 16,1 | 3125 | 1745 | 1370 | 3800 | |||

| ZL-400 | 0,4 | 0,405 | 0,61 | 24,2 | 3610 | 1935 | 2220 | 5145 | |||

| ZL-630 | 0,63 | 0,405 | 0,61 | 32,2 | 3868 | 2165 | 2280 | 6490 | |||

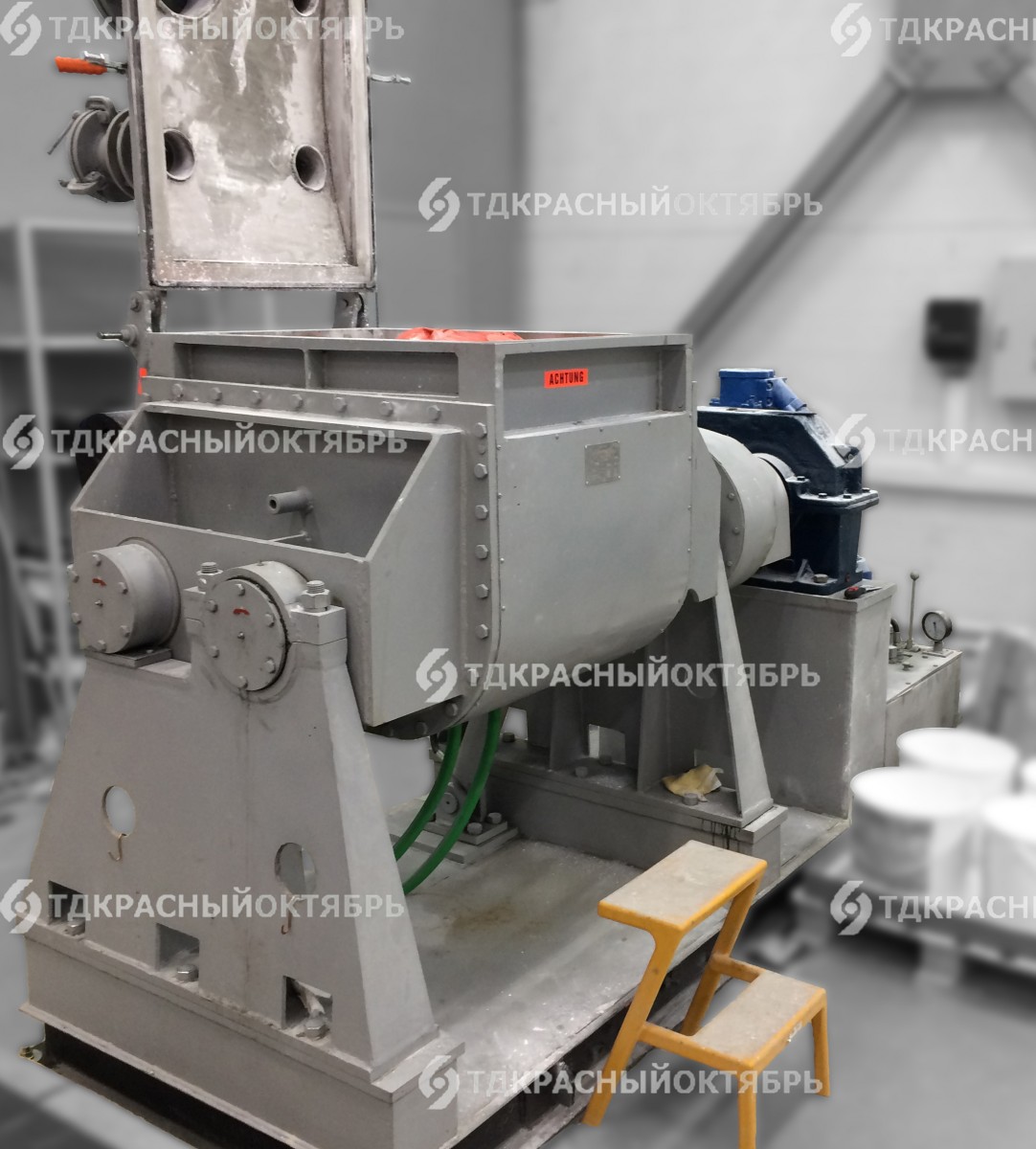

Mixers of batch type ZSH

In mixers type ZSH the finished product is unloaded with the lid closed by squeezing the product with a screw. The auger has a heated casing and a flange connection. A pipeline, spinneret, etc. can be connected to the flange connection.

Characteristics of mixers of periodic action of ZSH type

| Mixer size | Working volume, m3 | Rotational speed of slow-speed rotor, s-1 | High speed rotor speed, s-1 | Screw rotation frequency, s-1 | Working temperature, °С | Installed power, kW | Pressure in the chamber, MPa | Pressure in the shirt, MPa | Overall dimensions max, mm | Weight max, kg | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| length | width | height | ||||||||||

| ZSH-100 | 0,01 | 0,64 | 0,97 | 0,97 | 0 to +160 | 15 | 0,01 | 0,6 | 2790 | 1170 | 1600 | 2547 |

| ZSH-400 | 0,4 | 0,375 | 0,625 | 0,79 | 33 | atm. | 3310 | 1630 | 2265 | 5427 | ||

To control and control the operation of the mixers, the control panel and the power cabinet.

From the control panel, the rotor and auger electric drives are put into operation, the direction of rotation of the rotors and the screw are reversed, as well as the on-off control. The control panel is located in the working area.

In the power cabinet are placed switches, starters and other power electronic fittings. The power cabinet is located in an explosion-proof room.

| Parameter | Power cabinet | Remote control |

|---|---|---|

| Width, mm | 500 | 456 | Depth, mm | 650 | 153 | Height, mm | 1000 | 1000 |

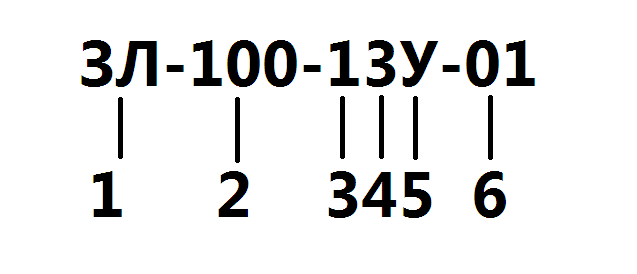

Symbol for ordering:

| 1 - Type of mixer (ZSH, ZL, SND, PU); |

| 2 - Working volume; |

| 3 - Explosion proof (1, 2); |

| 4 - Heat exchange element (3, 5); |

| 5 - Material design (Y-carbon steel, K-corrosion-resistant steel); |

| 6 - Sequence number of the model |

Symbol for ordering: (questionnaire No. 3) ZL-100-13U-01

Mixer type (ZSH, ZL, LPD, PU) - Working volume - Explosion proof (1, 2) - Heat exchange element (3, 5) - Material design (U-carbon steel, K-corrosion-resistant steel) - Model serial number

Industrial mixer, designed for kneading and stirring with the possibility of heating or cooling various semi-solid masses, pastes, glues, soft plastic masses. Today it is actively used in the chemical, pharmaceutical, cosmetic, food, and many other areas of modern industry. In animal husbandry, the mixer is quite in demand when used at various feed mills, farms, animal farms, poultry farms and various subsidiary farms where it is used to enrich feed, achieve higher quality rations, and improve their overall biological usefulness.

The most widespread use of such mixers was in the food industry, as well as in pharmaceutical production.

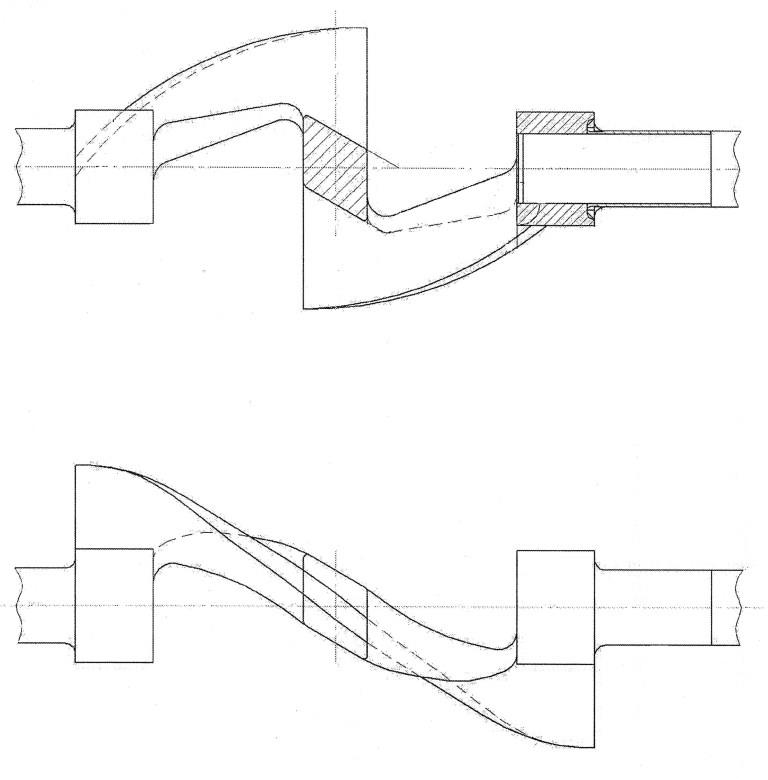

Depending on the physical and mechanical properties of the milled material, the mixers type ZL and ZSH are equipped with rollers of different configurations:

Mixer V=0,21m3

It is intended for mixing of powdered components in food, pharmaceutical, cosmetology and other industries, it is used for preparation of medicinal products (mixing of loose components) in the pharmaceutical industry. Mixing of components occurs when the mixer drum rotates. Loading and unloading of components is carried out through two hatches located on the drum. For safety, it is equipped with a protective cover. It is made of stainless steel. The outer surface of the mixer and the inner mixing chamber are polished. At the request of the customer, the mixer can be manufactured in different sizes.

Specifications

| Index | Value |

|---|---|

| Nominal body volume, l | 210 |

| Working pressure in the housing | atmospheric |

| Speed of rotation of the body, rpm | 22,4 |

| Power, kWt | 1,5 |

| Type of drive | ЗМП50-22,4-570-110-УЗ |

| Basic structural material | Steel 12Х18Н10Т |

| Mass, kg | 375 |

Mixer of continuous action SND-1500

Mixer of continuous action SND-1500 with a jacket for heating or cooling is designed for the preparation of pastes of lead-acid batteries and other similar materials. The mixer is designed for operation in rooms with an explosive atmosphere. The mixer is equipped with an electric motor series AIR.

Technical specifications

| Position number | Parameters | Unit of measurement | Indicators |

|---|---|---|---|

| 1 | Productivity | kg/hr | 1500 |

| 2 | Working pressure: | ||

| - in the mixing chamber | - | atmospheric | |

| - in a shirt | MPa (kg/сm2) | 0,2 (2,0) | |

| 3 | Working temperature | °С | +5 to + 50 |

| 4 | Electric motor power | kW | 11 |

| 5 | Rotational speed of working bodies: | ||

| - front | s-1(rpm) | 3,3 (31) | |

| - posterior | с-1(rpm) | 3,3 (31) | |

| 6 | Dimensions: length * width * height | mm | 3820*930*1200 |

| 7 | Mass mixer | kg | 1538 |

Puchonulator PU-1200

It is designed for removal from lime milk, which is a suspension of Ca(OH)3 with a CaO content of up to 20%, sand and small nedopal (gris, ash).

Technical specifications

| Position number | Parameters | Unit of measurement | Indicators |

|---|---|---|---|

| 1 | Volume: | ||

| - nominal | m3 | 1,5 | |

| - working | m3 | 1,2 | |

| 2 | Working pressure | - | atmospheric |

| 3 | Working temperature | °С | +5 to +25 |

| 4 | Rotational speed of working bodies: | ||

| - cesspool mixer | sec.-1(rpm) | 0,024 (1,4) | |

| - auger | sec.-1(rpm) | 0,37 (22,4) | |

| 5 | Installed power: | ||

| - a drive of a cesspool mixer | kW | 2,2 | |

| - auger drive | kW | 0,25 | |

| 6 | Working environment | - | Non-explosive and non-flammable, non-corrosive |