Chemical reactors with agitating device

EVROHIMMASH K.O. LTD manufactures apparatuses, disolvers, fermenters, massecuite mixers, etc. vertical and horizontal type with various types of agitating devices for carrying out various technological processes in liquid single-phase and multiphase media.

The working environment in the body of the device is neutral, aggressive, fire-hazardous, explosive or toxic liquid, emulsion, gas-liquid mixture or suspension with mass concentration of solid phase not more than 30%. In the jacket and coil, tap water or recycled water, brine, condensate, saturated steam or a high-temperature organic coolant.

Apparatus with agitators are manufactured according to standard, as well as necessary parameters of the customer.

Types of apparatus with a mixing device:

| Name of apparatus | Sketch | Nominal volume, m3 | Pressure conditional, MPa | Appointment |

|---|---|---|---|---|

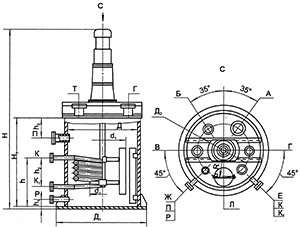

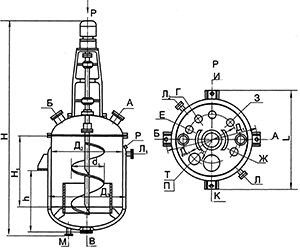

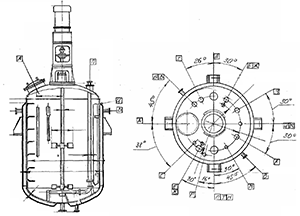

| Apparatus with flat bottom and cover |

|

1,0; 2,0; 3,2; 5,0; 6,3; 10,0; 16,0; 25,0; 32,0; 50,0; 75,0 | 0 | for the preparation of suspensions at atmospheric pressure |

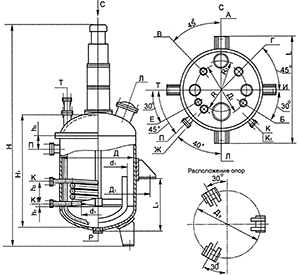

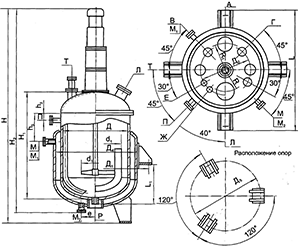

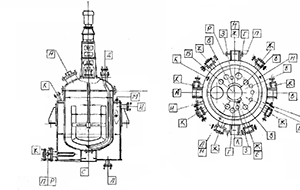

| Apparatus with elliptical bottom and cover |

|

1,0; 2,0; 3,2; 5,0; 6,3; 10,0; 16,0; 25,0; 32,0; 50,0; 75,0 | 0,3; 0,6; 1,0; 1,6 | for carrying out various chemical processes under pressure |

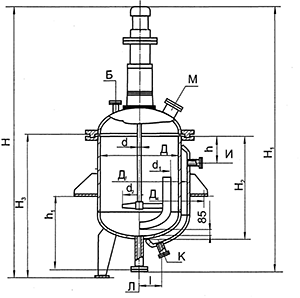

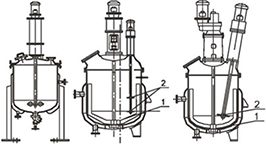

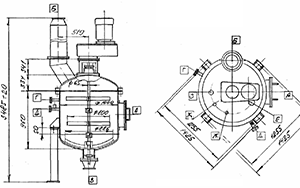

| Apparatus with elliptical bottom and removable elliptical cover V=0,025-0,63 m3 |

|

0,025; 0,04; 0,063; 0,1; 0,16; 0,25; 0,4; 0,63; 1,0-75,0 | 0,3; 0,6; 1,0; 1,6 | for carrying out various chemical processes under pressure |

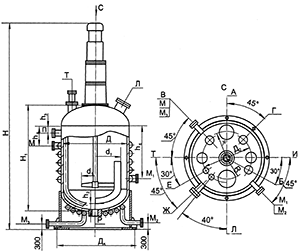

| Apparatuses all-welded with an elliptical bottom and a lid, with a half-pipe jacket |

|

10,0; 16,0; 25,0; 32,0; 50,0 | 0,3; 0,6; 1,0; 1,6 | or carrying out various chemical processes under pressure |

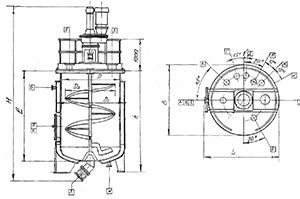

| Apparatuses with an elliptical bottom and a removable elliptical lid with a screw agitator |

|

3,2; 5,0; 8,0; 10,0 | 0,3; 0,6; 1,0; 1,6 | or carrying out various chemical processes under pressure |

| Apparatus with elliptical bottom and lid and a smooth welded jacket |

|

1,0; 2,0; 3,2; 5,0; 6,3; 10,0; 16,0; 25,0; 32,0; 50,0 | 0,3; 0,6; 1,0; 1,6 | for carrying out various technological processes in liquid media with heating |

| Dissolvers |

|

0,1 - 25,0 | 0,3; 0,6; 1,0; 1,6 | for the preparation of paints by mixing varnishes, drying oils, solids (pigments, fillers), solvents, plasticizers, siccatiles |

| Thermoformers |

|

3,2 - 25,0 | 0,3; 0,6; 1,0; 1,6 | for heat treatment of pulp and juice, as well as for infusion with mashing wort in the production of vintage dessert wine materials |

| Fermenters |

|

2,0 - 25,0 | 0,3; 0,6; 1,0 | for the production of viruses, bacteria in nutrient media in the microbiological industry |

| Apparatuses with electric heating |

|

1,0; 2,0; 3,2; 5,0; 6,3; 10,0; 16,0; 25,0; 32,0; 50,0 | 0,3; 0,6; 1,0 | for carrying out technological processes in liquid media with stirring and heating with heating elements |

| Continuous steamer |

|

0,8 | 0,3; 0,6; 1,0 | for moisture thermal treatment of cereals or grains |

Material of manufacture of devices: ст3, 09Г2С, 12Х18Н10Т, AISI304, AISI201, AISI316, titanium alloys, polypropylene containers, fiberglass.

Application of an anti-corrosion and wear-resistant coating.

Production volumes from 50 l to 150 m3 with the following types of agitators:

- Containers and apparatus with a paddle stirrer;

- Containers and apparatus with turbine mixer;

- Containers and apparatus with a propeller stirrer;

- Containers and apparatuses with turbine clamp;

- Tanks and apparatus with belt mixer;

- Containers and apparatus with a disk stirrer;

- Tanks and apparatus with a frame mixer;

- Tanks and apparatus with anchor stirrer;

- Containers and apparatus with a comb stirrer;

- Containers and apparatus with a chain stirrer;

- Vertical tanks with combined mixer;

- Dissolvers;

- Capacities and apparatus with heating jacket, coil;

- Containers and apparatus with electric heating;

- Containers for dosing and water treatment systems;

- Capacities of special geometry-hexahedral, octagonal tanks;

- Stainless, food, chemically resistant containers with a stirrer with a polished or matt surface;

- Ferrous metal tanks with agitator;

- Fiberglass tanks with agitators in the crate or without a crate on its own support;

- Open and closed containers with agitators;

- Ground horizontal tanks with a stirrer;

- Rectangular tanks with agitator;

- Contact vats for the concentration industry up to 50 m3;

- Trowels for the concentrating industry up to 10 m3;

- Non-standard containers according to the terms of reference;

- Completion of tanks with additional equipment.

Stainless steel tanks with vertical mixer, propeller mixer, frame, turbine, multi-row, combined, one or two impellers on shaft.

They are designed for mixing various liquid and medium viscosity media.

Manufacturing according to the customer's parameters. Completion of additional equipment.

Apparatuses with a mixing device with special mixers are used mainly for products of increased density, suspended solids, where the use of internal partitions causes stagnant zones and precipitation. Six and eight bottles allow to reduce the funnel, formed with intensive mixing. Such vessels are used in ceramic industries for the dissolution of clay in combination with a propeller high-speed stirrer, intermediate tanks for maintaining suspensions before feeding to spray nozzles, etc., brick factories, in the food industry for the preparation of syrups in combination with a frame mixer.

Capacities plastic, fiberglass. Capacities plastic, fiberglass with a stirring device (stirrer).