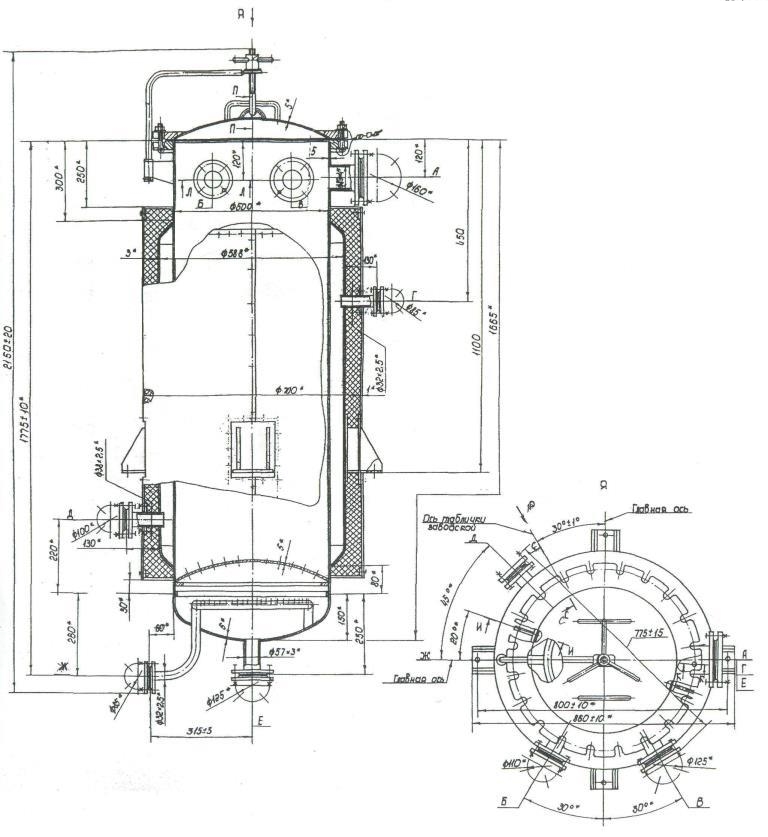

Percolator

Purpose: Designed for carrying out extraction processes from vegetable raw materials in the production of tinctures.

Capacity of percolator 250 l.

Diameter of nozzles

| Notation | Appointment | Number, pcs. | dy, mm |

|---|---|---|---|

| А | For the escape of vapors | 1 | 80 |

| Б | For filling | 1 | 50 |

| В | For air vent | 1 | 25 |

| Г | For steam | 1 | 25 |

| Д | For condensate | 1 | 25 |

| Е | For the bottom sruska | 1 | 25 |

| Ж | For bubbler | 1 | 25 |

Technical specifications

| Capacity percolator, l | 250 |

| Working pressure in the apparatus, kg/cm2 | 3 |

| Working pressure in steam jacket, kg/cm2 | 3 |

| Diameter of percolator D, mm | 500 |

| Thickness of percolator wall S1, mm | 5 |

| Diameter of steam jacket D1, mm | 350 |

| Wall thickness of steam jacket S2, mm | 4 |

| Height of working part of percolator H1, mm | 1665 |

| Percolator height H, mm | 2215 |

| Weight percolator, kg | 440 |