Heat exchangers of the "vessel in a vessel" type

Heat exchangers steel enameled type "vessel in a vessel" are designed for heat exchange with corrosive liquids.

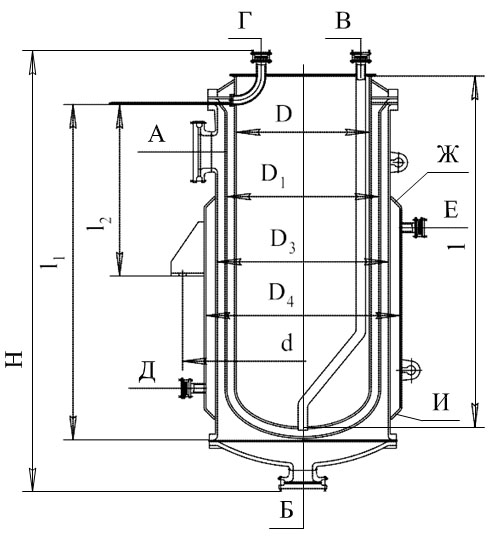

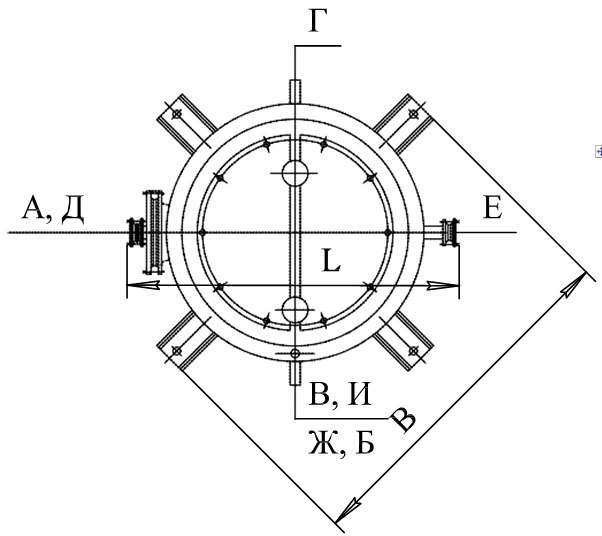

The heat exchanger consists of a shell with a jacket and an inner vessel.

Working pressure, MPa (kgf/cm2):

in the case: 0,6 (6,0) or residual not less than 0.04 (300 mm Hg)

in a shirt: 0,6 (6,0)

Permissible wall temperature:

in the case:

• in an acidic environment - from minus 20 to plus 200°C;

• in a neutral environment - from minus 20 to plus 150°C;

• in an alkaline medium:

○ at pH=11 - from minus 20 to plus 130°C;

○ at pH=12 - from minus 20 to plus 110°C;

○ at pH=13 - from minus 20 to plus 90°C;

○ at pH=14 - from minus 20 to plus 80°C.

in a shirt: from minus 20 to plus 200°C.

Fittings table

| Area of heat exchange, m2 | Characteristic | |||||||

|---|---|---|---|---|---|---|---|---|

| А | Б | В | Г | Д | Е | Ж | И | |

| Product login | Product yield | Water inlet or steam outlet | Water outlet or steam outlet | Water inlet or steam outlet | Water outlet or steam outlet | For air outlet | Condensate drain | |

| Nominal passage, mm | ||||||||

| 2,0 | 100 | 100 | 20 | 20 | 40 | 40 | М10х1 | М10х1 |

| 4,0 | 150 | 100 | 40 | 40 | 40 | 40 | М10х1 | М10х1 |

| 6,0 | 150 | 100 | 40 | 40 | 40 | 40 | М10х1 | М10х1 |

| 8,0 | 200 | 100 | 40 | 40 | 40 | 40 | М10х1 | М10х1 |

| 10,0 | 200 | 100 | 40 | 40 | 40 | 40 | М10х1 | М10х1 |

Technical characteristics of heat exchangers

| Notation | Heat exchange surface, m2 | D, mm | D1, mm | D2, mm | D3, mm | d, mm | l, mm | l2, mm | l3, mm | Overall dimensions | Weight, kg | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| length, L | width, B | height, H | |||||||||||

| СЕc 2,0-12 | 2,0 | 207 | 305 | 404 | 500 | 608 | 1125 | 1120 | 520 | 810 | 668 | 1490 | 442 |

| СЕc 4,0-12 | 4,0 | 414 | 500 | 600 | 700 | 980 | 1630 | 1600 | 835 | 985 | 1040 | 2120 | 1180 |

| СЕc 6,0-12 | 6,0 | 500 | 600 | 700 | 800 | 1080 | 1960 | 1900 | 800 | 1085 | 1140 | 2450 | 1680 |

| СЕc 8,0-12 | 8,0 | 700 | 800 | 900 | 1000 | 1280 | 1825 | 1750 | 840 | 1310 | 1340 | 2310 | 1960 |

| СЕc 10,0-12 | 10,0 | 700 | 800 | 900 | 1000 | 1280 | 2175 | 2100 | 1215 | 1310 | 1340 | 2660 | 2430 |